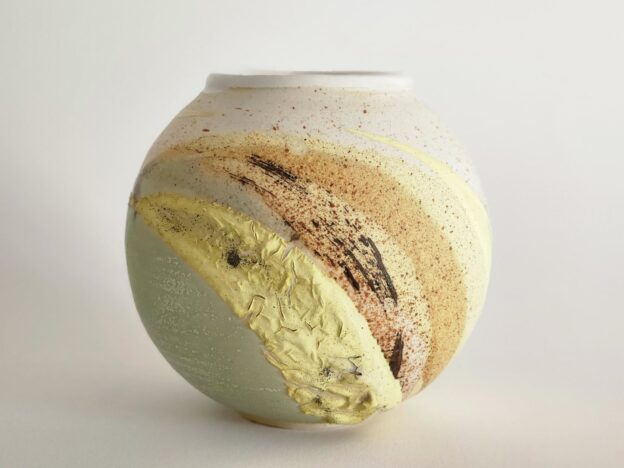

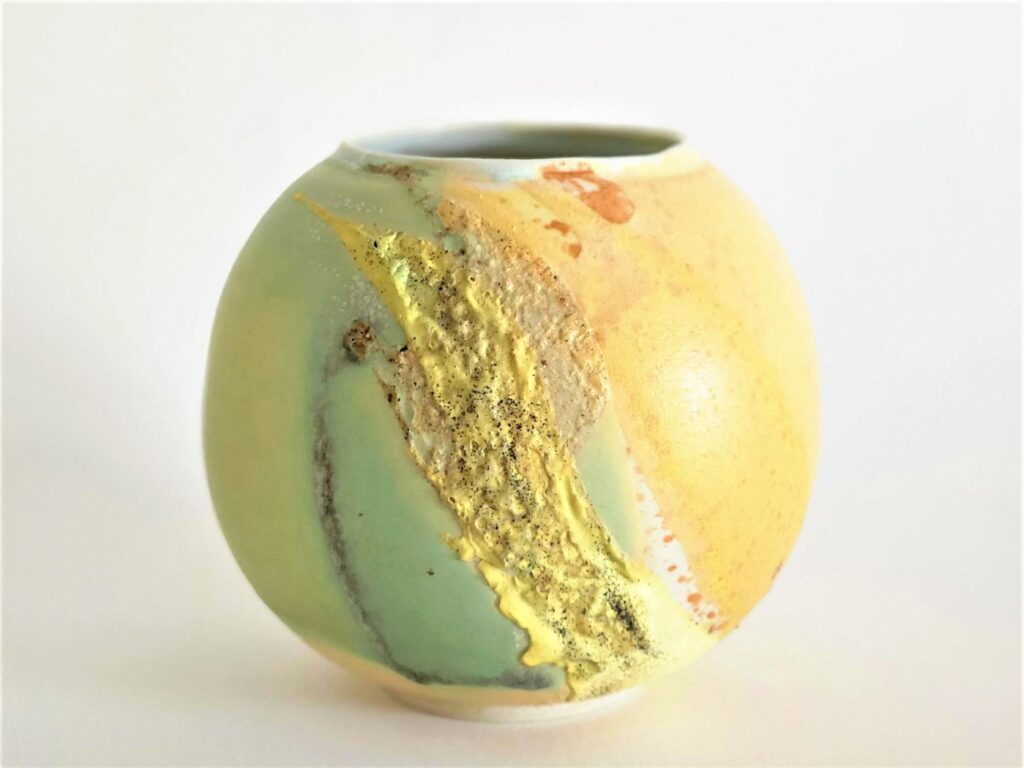

Reeds waving in the breeze, and leaves floating on the water, all bathed in sunlight.

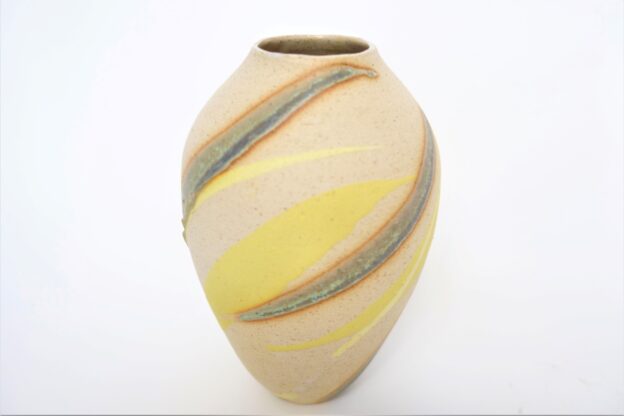

Wheel-thrown, using reclaim clay at Olaria Mealha, Lagos, Portugal. Only having time to bisque it there, I glazed it once back home in Ottawa. The streams of glaze create an attractive flashing just where they edge onto the bare clay. Did the gas kiln bisque firing in Lagos create that strong effect? Was it iron in the reclaim clay itself? All I know is that I haven’t, so far, been able to repeat it — and doubt whether I ever will. Oh well. I like it.

Wheel thrown. Stoneware; glaze fired to cone 6, in oxidation.

Height: 17 cm, Width: 10 cm